1) What is involved ?

Rehabilitation involves restoring a well or a borehole no longer in use or with too low a flow rate back to its initial state and sometimes improving it by using miscellaneous reconstruction treatments or methods.

2) Who use this means and since when ?

The majority of players have been potentially involved for a long time :

- authorities, local authorities, village communities and users.

- technical departments, contractors or craftsmen for the implementation.

- NGOs, lending institutions.

3) Why ?

There are a variety of reasons for rehabilitating a well or borehole :

- Groundwater pollution (latrines, excrement, animal excrements)

- Not enough depth, therefore insufficient water.

- Drop in the water table level resulting in reduced output and even drying up.

- Damaged or insufficient concrete casing or well liner encouraging the risk of water pollution.

- Equipment breakdowns (pumps, winch, etc.)

- Contamination and lack of cleanliness around the well.

4) Who is primarily concerned ?

All villages, even some near-urban districts, where wells or boreholes are not designed, constructed or serviced properly.

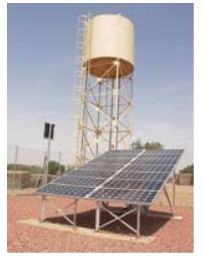

Photo Caritas Burkina

5) What does this process involve ? How is it applied ?

Before deciding to rehabilitate a well, the technical feasibility and cost of the operation must be assessed. It is also useful to know and analyse damage, previous failures, their frequency and reasons in order to choose the correct technique.

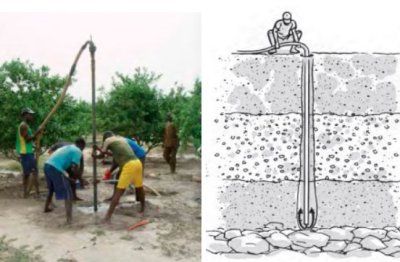

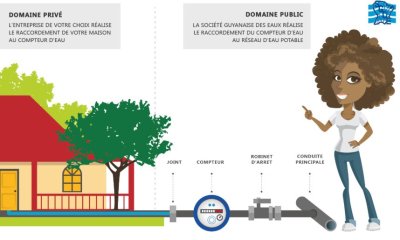

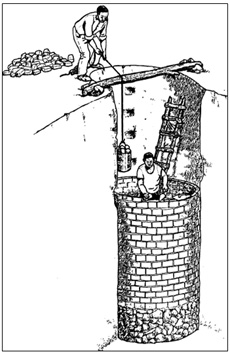

Creating an internal coating (WEDC document)

a) Rehabilitation of dug wells

Various types of work can help to rehabilitate and supplement a dug well :

Increasing the well depth

- This involves digging out the bottom of the well to prevent a groundwater recession following a drop in the level of the water table.

- The ideal solution is that the bottom of the well remains below the level of the water table during the driest period in the year.

Internal well coating

- This can involve renovating the old casing or installing a first coating for a simply dug well.

- Various materials can be used depending on the characteristics of the well and the options on the site : bricks, natural stone, concrete blocks and concrete rings.

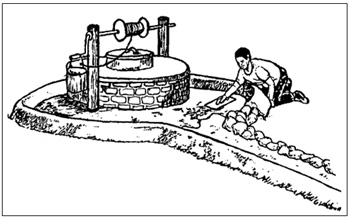

Raising the outside wall of the well

- The aim is to prevent foreign matter penetrating the well by constructing a coping (raised edge) 80 to 100 cm high

Well lid

- The lid prevents children especially but also animals from falling accidently into the well. It also stops plants, crumbly earth or dust from penetrating the well.

- A hard lid or removable lid are alternative or additional solutions

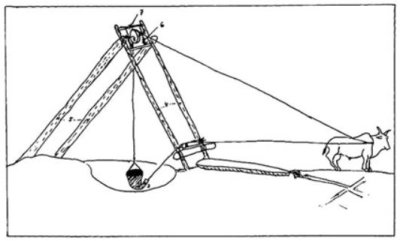

Improving the water collection or pumping methods

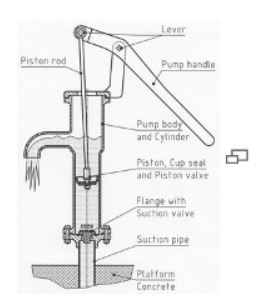

- Installing a winch makes it easier to extract the water.

- Similarly, installing a hand pump or a mechanised pump makes users less tired and avoids contaminating the water with well buckets which are often not clean enough or have dragged on the ground.

Arranging the immediate surroundings

- Stagnant water around the wall is unpleasant for the users, a potential source of pollution and encourages the proliferation of mosquitoes.

- It is highly recommended to cement over the ground (raft) with an edge and a runoff channel towards a basin, a watering place or a vegetable garden.

- Lastly, it is also important to protect the well from being reached by animals by fencing it off.

Constructing a cement coating around a well (WEDC document)

Removing latrines, excrement deposits and animals from around the well

- It is recommended to keep the well surroundings clean over a radius of 25 m at least.

- A wall or protective barrier could make it easier to protect the well by keeping the animals away and preventing the water being polluted by excrements.

b) Rehabilitating driven wells and boreholes (drilled wells)

Photo RWSN

Certain types of work similar to the previous work is required to rehabilitate driven or drilled wells, especially :

- Raising the outside wall (coping) of the well

- Arranging the immediate surroundings

- Removing latrines, excrement deposits and animals from around a shallow well

Other work is more specific to driven or drilled wells :

Cleaning the capture section (pipes, pump)

- if the well is not obstructed, any equipment in the well is removed and compressed air is blown into the borehole to clean it and unclog the strainer that may be clogged

- chemical treatment can also be envisaged with the help of competent technicians to dissolve the deposits on the pipes or strainers

Overhauling pumping equipment

- Overhauling manual pumps

- Changing the submerged pumps that have broken down repeatedly or for long periods

Far more cumbersome operations involve overhauling the borehole piping to change pipes or recase the borehole.

This technically complex and costly work can only be justified for deep boreholes in areas where there is no alternative water resource.

6) Special difficulties and remedies

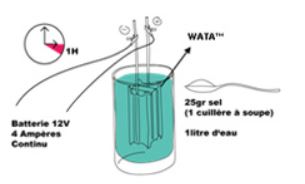

Before any well or borehole goes back into service following rehabilitation, it must be disinfected to eliminate any bacterial contamination introduced by the workers, the materials and even the surface of the water during the work.

Bleach can be used as a disinfectant, respecting the following stages :

- pour the required quantity of bleach into the well (and mix it with the well water if possible).

See the table below from Health Canada for the quantity

| Table 1 : Disinfecting the well water using odour-free household bleach (about 5.2 p. 100 hypochlorite) | ||||

| Depth of water in the well | Volume of bleach added | |||

| Piping diameter 15 cm (drilled well) | Casing diameter 90 cm (dug well) | |||

| New well* | Existing wells* | New well* | Existing wells* | |

| * New wells require a chlorine concentration of 250 parts per million (ppm) for effective disinfecting whilst existing wells only need 50 ppm chlorine. | ||||

| 1 m | 100 ml | 20 ml | 3.2 l | 0.6 l |

| 3 m | 300 ml | 60 ml | 9.8 l | 2.0 l |

| 5 m | 500 ml | 100 ml | 16.5 l | 3.0 l |

| 10m | 1,000 ml | 200ml | 32.0 l | 6.5 l |

- pump sufficient water to disinfect the pump and the pipes ;

- leave the chlorine to act in the well and the pipes for at least 24 hours then let the water flow until the smell of chlorine has completely disappeared ;

- sample the water for bacteriological analyses (total coliforms, faecal coliforms). See sheets E 26 and E 27 on water analysis methods and means

Another sample must be taken one week after the disinfecting operation for bacteriological analyses.

The disinfecting stages in this well must be repeated if the bacteriological analysis indicates contaminated water in the well.

7) Main advantages and drawbacks

The rehabilitation of existing wells aims to supply a community without being forced to create a new well, thereby restricting the costs. Before committing to the project, it is important to make sure that the renovated well will be able to cover the needs of both its current and future users and that it will meet the expectations and motivations of the village community.

In some cases, the report on the prior diagnosis of the well can result in the rehabilitation project being dropped and, if necessary, the well being neutralised if the quantity and quality objectives corresponding to the planned uses for the water cannot be achieved or if there is too much damage to the well.

8) Cost

The cost of rehabilitating a well varies according to the type of well, its environment and the work carried out. It is therefore difficult to estimate it accurately.

9) Observations, recommendations and suggestions

The lack of well servicing and repair can halt pumping or drawing of water due to breakdowns in operation. It also downgrades the quality of the water and therefore causes illness.

Such malfunctions lead to huge numbers of dug or drilled wells being abandoned every year worldwide and to envisaging committing, if necessary, to a rehabilitation operation.

Raising the awareness and educating users to the need for maintenance and the installation’s maintenance and servicing tasks are therefore essential for sustainable operation of a well.

(see sheet E 32 on well maintenance)

10) Achievement examples

In Mali, an extensive national survey was carried out in 2001-2002 to list the modern wells and boreholes. It showed that one third of manually-driven pumps had broken down and that some of them had been abandoned for several years. Certain Circles (departments) had functionality rates of less than 30% and not one enjoyed rates higher than 75%, with the national average set at 66%. To the lack of upkeep and the management problems is added the age of some engineered structures (over twenty years old), where spare parts often no longer exist.

The Mali Government has therefore launched several rehabilitation campaigns since 2002.

To find out more, see the Guide to creating boreholes in Mali produced by the Association Forages-Mali, available on the hereafter PS Eau site : http://www.pseau.org

[GUIDE POUR LA RÉALISATION DE FORAGES AU MALI->http://www.pseau.org/outils/ouvrages/forages_mali_guide_realisation_forages_mali.pdf]

11) Where to obtain further information

a) Website

- Health Canada : four-page summary guide on treating, servicing and maintaining water quality in a well

http://www.hc-sc.gc.ca/ewh-semt/pub...

- WHO (World Health Organisation) : The Health Technician Manual. (pages 30 to 32)

http://whqlibdoc.who.int/publicatio...

- University of Maryland. Thomas H. Miller, Waterwells and their Maintenance Guidelines : (good maintenance practices)

http://extension.umd.edu/learn/wate...

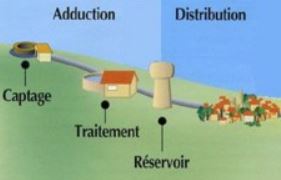

Photo Caritas Togo Region of Savanes

b) Video

- Swissaid Association : Rehabilitation of drinking water wells in Guinea-Bissau. Available online at :

http://www.youtube.com/watch?v=s0JZ...